Hans Koch GmbH | Glandorfer Straße 25 | 49196 Bad Laer | Telefon 05424 2972-0 | E-Mail: info@scheerkoch.de

Woodworking machinery and tools

Consultancy – Sales – Service

Menu

Machinery

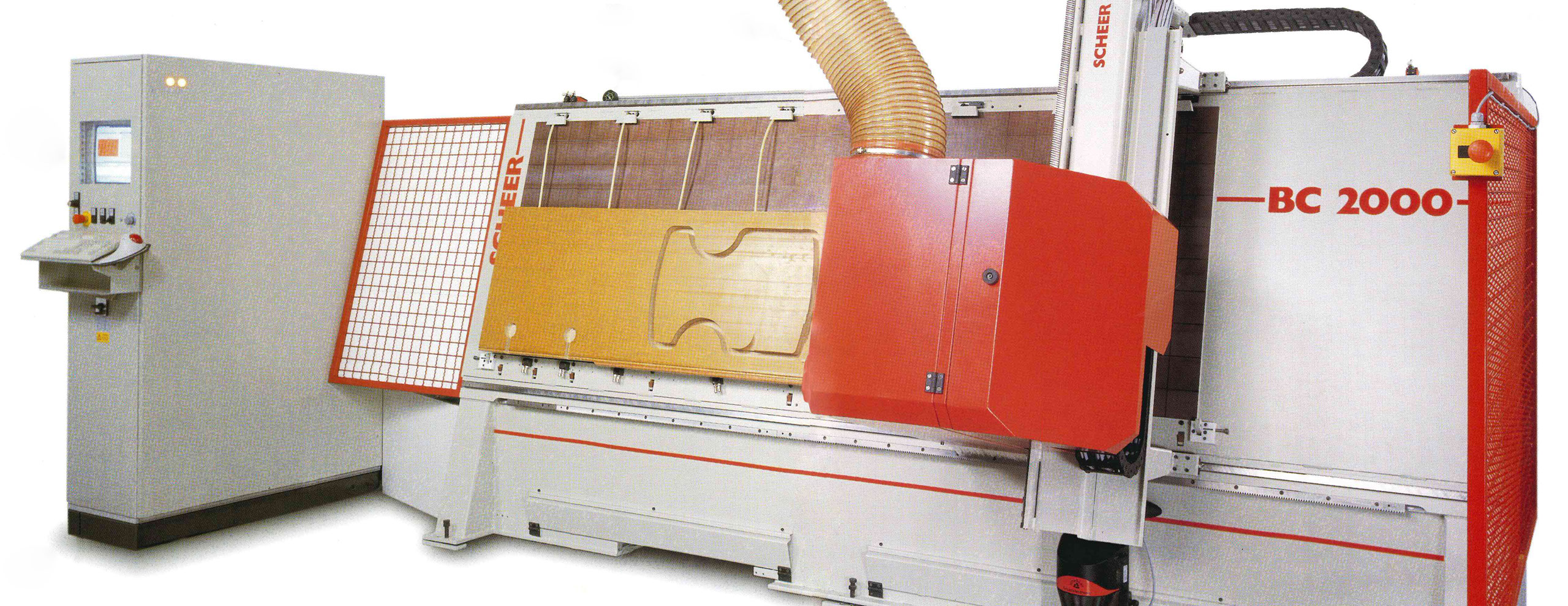

Towards the vertical -

with the drilling and routing centre

from the Scheer BC series!

Why machine panelled materials horizontally?

A machining process does not only begin when the workpiece is securely and accurately positioned in the processing machine. The cost and effort to move materials to and from the machine are often underestimated. When looking at the individual operations, it is noticeable that the material transport is labour intensive. Mainly machine operators, who are professionally trained and actually should be entrusted with other work, spend a lot of time and energy on the task. The workpieces are to be placed into the machines and taken out after machining. Vertical boards often need to be brought into a horizontal position in order to be fed into the processing machine. Additional time, effort and control are required when securely placing the boards on the material stops. The machining process takes place within the machine and is not necessarily straightforward. The workpiece removal is designed similarly. This mode of operation is not necessarily cost-effective and user-friendly. Some machines can create the impression as if economic and ergonomic aspects are not necessarily part of construction and design.

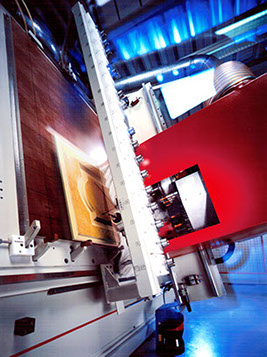

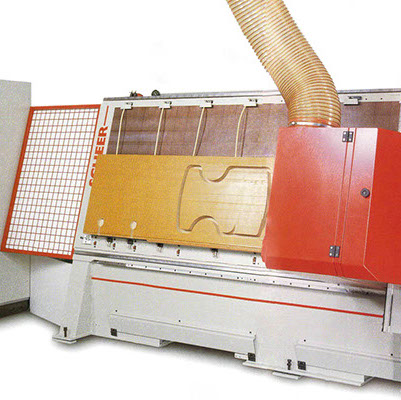

The "upright" drilling and routing centre

The development and construction of the Scheer drilling and routing centre stipulate important specifications, one of which is the spatial footprint of the machine, limiting it to a minimum without compromising easy access for operation and maintenance. The portal construction, known in mechanical engineering as the familiar portal construction (gantry and table design), was combined with an inclined workpiece support. The advantage of this type of construction is the easy and effortless transport of the workpieces to the machine. Further attention was paid to visual clarity of the workpiece support, which is equipped with a variety of clamps and stoppers. A further important point was to keep set-up times to a minimum. The close cooperation of construction, production and practicality resulted in the “upright” drilling and routing centre. All tasks, ranging from positioning of the workpiece, tool usage and machining operation, are easily and simply executed.

The moving tool changer for the powerful routing unit guarantees short automatic changeovers for routing tools and/or machining units. Should manual access in exceptional cases be required, the upright design facilitates the task. There is no need for the operator to access the machine from below. The tool changer is accessible in an easy and safe manner.

Efficient and cost-effective production

The vertical machine design, workpiece clamps and the visible workpiece, represent an ergonomic workplace for the operator. Feeding is simple and effortless, the workpiece stops are visible and the tool changer is easily accessible when required. Error-free working and cost efficient products can be achieved due to easily acquired machine programming/control as well as simple operation of the unit.

Considering heavy material such as kitchen worktops, front doors and interior doors, aluminium plates, etc., they can be easily carried in a vertical manner and mounted in the clamping system of the machine. The workpiece is placed on the stop bar and is automatically positioned by gravity at zero. Once machining has been started, the stops swing to the side and the workpiece can be machined from all sides. All required surface and frontal drilling/routing works are carried out in one process in a precise and space-saving manner and with a high repeat accuracy.

Cleanliness in the workplace

The highly effective and centrally placed saw chips and dust extraction system, ensures cleanliness in the workplace. The machined material drops down and will be removed effectively by suction. Deposits on the workpiece or the workpiece support will thus be prevented. Workpiece format changes that require different positioning of the material suction can be carried out without time-consuming cleaning processes of the machine. Optionally the machine displays the suction position by means of a laser pointer. Alternatively, all workpiece contours can be projected onto the workpiece support surface.

Active personnel protection

The sophisticated machine design, the Scheer BC has been built since 1990; it provides an alternative to the usual mats as personal protection equipment, the use of a moving security scanner, which switches the machine to ‘creep mode’ if there is a risk of danger and only in case of imminent danger triggers the "emergency shutdown ". Accidental "emergency stop" will not be initiated, yet the personnel protection is guaranteed.

High availability

The manufacture of such sophisticated machine technology, Made in Germany, is subject to strict quality control. The material components were chosen in accordance with performance and functionality for high product demands and long service life. Thorough operator training, good customer service provided by us and optimal maintenance ensure that machine-related production losses become a thing of the past and only happen rarely with this line of machine.

Aside from the value for money aspect, these are the reasons that make the drilling and routing centre made by Scheer so popular amongst users.

The Scheer BC 2001 is suitable not only for engineered wood but also for machining a variety of materials such as plastics, sandwich and composite materials as well as non-ferrous and precious metals. For drilling and routing tests on special materials / workpieces various machines and tools are at your disposal in our showroom.

Standort Bad Laer – HANS KOCH GMBH, Glandorfer Strasse 25, D 49196 Bad Laer - Hardensetten